23L Microwave Oven Front Panel Frame Press Tool Stamping

• Product Name: Microwave Oven Front Panel Frame;

• Type: Side door;

• Product Capacity: 23L ;

• Product Material: SUS304;

• Material Thickness: 0.5mm;

• Product Size: 483*262*42(mm)

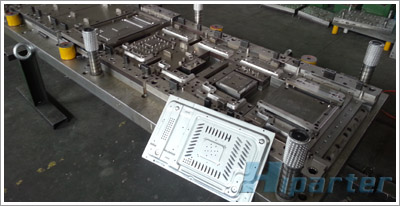

Stages of the Press Tool Stamp :

• Reasonable stages arrangement, less issues, less repair;

• Have made molds for over 90% sheet metal parts of Microwave Oven;

• Tool Type: Tandem tool;

• Tool Stages:3

• Press Tonnage: 160T

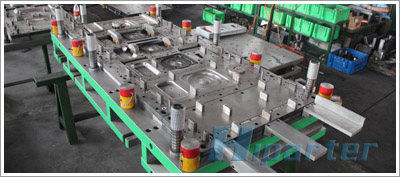

Tool Structure :

Hiparter has 20+ experiences in designing and manufacturing Stamping Tooling. We have a variety of microwave oven panel and other home appliances stamping tooling manufacturing process capabilities.

Stamping Tooling Manufacturing Capacity :

1)Stamping tooling machining equipment more than 28 sets

2)Slow speed wire cutting machine and middle speed wire cutting machine more than 11 sets

3)Fully equipped with grinder machine, milling machine, drilling machine, NC machining, wire cutting machine, etc.

4)Almost all the machining process completed in-house.

5)We can guarantee the quality and lead time.

Tools Processing :

Split tooling drawings, mark processing methods and control processing quality.

In order to ensure that each stamping tooling is qualified before out our factory, we have a strict quality control mechanisms. We will inspect each stamping tooling as the following ways.

1) Hardness tester

2) Chemical analysis

3) Digital Measuring Projector

4) Dynamic Balancing Tester

5) Universal testing machine & Coordinate-Detector for CNC machining

If there is any quality problems, we will take full responsibility.

Choose Hiparter, you will set your mind at rest!

Factory Progressive Microwave Oven Panel Stamping Tool

•Hiparter is a professional manufacturer of stage metal stamping tools and progressive stamping tools, committed to tool design, tool manufacturing and product production.

•In Hiparter, there is an innovative, dedicated and experienced team with more than 13 years experience.

Product descriptions from the supplier :

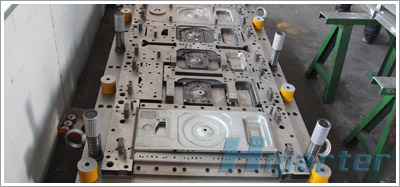

Part Name: Progressive Microwave Oven Panel Stamping Tool

Tool Type:Progressive Stamping Tool

Tool Material:SKH-9, DC53, SKD11,45#

Part Material:Stainless steel(SUS301, SUS304, SUS430 ) , etc.

Standard Part:MISUMI, PUNCH, FIBRO, DAYTON, DME, etc.

Manufacturing Machinery:Milling, Grinding, Boring, CNC, EDM, WEDM, Precision Flat Milling, Saw Machine

Press Machinery:45T~800T, Press machine, Punching machine, Forming machine

Inspection Machinery:CMM, Vision Projector, Micro-callipers, Laser Scanner, Alloy Analyzer

Forming Way:Punching, Blanking, Piercing, Bending, Forming, Deep Drawing, etc.

Tool Precision:High precision machining, minimum 0.02mm.

Lead Time:6 weeks for tool buidling, after the tool structure drawing confirmed.

Delivery:By sea or air, By air around 2-5 days, By sea around 10-30 days.

Other Oven Stamping Tool :

Hiparter has 20+ experiences in designing and manufacturing Stamping Tool. We have a variety of microwave oven panel and other home appliances stamping tool manufacturing process capabilities.

Stamping Tool Manufacturing Capacity :

1)Stamping tool machining equipment more than 28 sets

2)Slow speed wire cutting machine and middle speed wire cutting machine more than 11 sets

3)Fully equipped with grinder machine, milling machine, drilling machine, NC machining, wire cutting machine, etc.

4)Almost all the machining process completed in-house.

5)We can guarantee the quality and lead time.

Tools Processing :

Split tool drawings, mark processing methods and control processing quality.

In order to ensure that each stamping tool is qualified before out our factory, we have a strict quality control mechanisms. We will inspect each stamping tool as the following ways.

1) Hardness tester

2) Chemical analysis

3) Digital Measuring Projector

4) Dynamic Balancing Tester

5) Universal testing machine & Coordinate-Detector for CNC machining

If there is any quality problems, we will take full responsibility.

Customer acceptance tool :

Welcome a trial order with your drawing! There are value-added services for you!

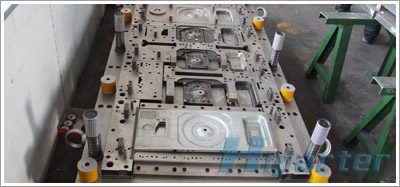

Qingdao custom Steel Metal Progressive Microwave Oven Stamping Die

•Hiparter made the microwave oven cavity, bottom plate and back panel.

•The material strip shown in the left picture is for the cavity progressive die. For the cavity, the material width is 720mm. The problems were successfully overcome, such as the distortion of strip during drawing process, products broken, can’t cut off neatly etc. Thus we got praise from customer.

Product Description :

Part Name: Progressive Microwave Oven Stamping Die

Part Material: JSC270D;

Material Thickness: 2mm;

ISO9001:2008 by SGS;

Made in Qingdao, China

Forming, Blanking,Forming, Trimming;

HS Code: 820730090;

Related progressive die :

Hiparter has 20+ experiences in designing and manufacturing Stamping Die. We have a variety of microwave oven and other home appliances stamping die manufacturing process capabilities.

Stamping Die Manufacturing Capacity :

1)Stamping die machining equipment more than 28 sets

2)Slow speed wire cutting machine and middle speed wire cutting machine more than 11 sets

3)Fully equipped with grinder machine, milling machine, drilling machine, NC machining, wire cutting machine, etc.

4)Almost all the machining process completed in-house.

5)We can guarantee the quality and lead time.

Dies Processing :

Split dies drawings, mark processing methods and control processing quality.

In order to ensure that each stamping die is qualified before out our factory, we have a strict quality control mechanisms. We will inspect each stamping die as the following ways.

1) Hardness tester

2) Chemical analysis

3) Digital Measuring Projector

4) Dynamic Balancing Tester

5) Universal testing machine & Coordinate-Detector for CNC machining

If there is any quality problems, we will take full responsibility.

Customer acceptance die :

Welcome a trial order with your drawing! There are value-added services for you!

Microwave Oven Inner Metal Door

The microwave oven cavity/chassis and door are made by metal-forming techniques, and then painted by electro-deposition, in which electric current is used to apply the paint.

Some Information:

1) Part material: ST14;

2) Material Thickness:0.5mm;

3) Die life:500,000 shots;

4) Punch of standard: PUNCH;

5) Die Type: Stage;

Our advantages:

1)Located in Qingdao,which is home appliance city with famous Haier, Hisense, Aucma;

2)Reasonable die structure to save cost, also guarantee the quality of products;

3)Tracking every steps for manufacturing the dies, to ensure the lead time;

4)Feedback in 24 hours;

5)All employees intend to make each product with zero defect;

6)Design software: AUTOCAD, UG, Pro/e, Solid works;

7)2~5 samples will be send to customers for inspection or assembly before shipping;

8)Advanced manufacturing, measuring and testing equipments

Oven Cavity and Door Manufacture:

1 )The process of manufacturing a microwave oven starts with the cavity and the door. First, the frame is formed using automatic metal-forming presses that make about 12 to 15 parts per minute. The frame is then rinsed in alkaline cleaner to get rid of any dirt or oil and further rinsed with water to get rid of the alkaline solution.

2) Next, each part is treated with zinc phosphate, which prepares it for electro-deposition.The resulting coating is about 1.5 mils thick. The parts are then moved through a paint bake operation where the paint is cured at 300 degrees Fahrenheit (149 degrees Celsius) for 20 minutes. The chassis or frame is mounted in a pallet for the main assembly operation. A pallet is a vise-like device used in conjunction with other tools.

The chassis or frame is mounted in a pallet for the main assembly operation. A pallet is a vise-like device used in conjunction with other tools.

3 After the door has been painted, a perforated metal plate is attached to its window aperture. The plate reflects microwaves but allows light to enter the cavity (the door will not be attached to the cavity until later, when the chassis is assembled).

The cooking chamber is in fact a Faraday chamber, and it prevents the waves from coming out of the oven. The oven door usually has a window for easy viewing, but the window has a layer of conductive mesh some distance from the outer panel to maintain the shielding.

China Microwave Oven Stamping Die

- Made in China;

- Product: Microwave oven;

- Capacity: 18L, 20L,21L,23L,25L,etc.

- Make stamping dies for almost all the sheet metal part of microwave oven;

- Reasonable die structure;

- Spare parts: PUNCH;

- Die Type: Progressive Die;

- Rich experience;

- ISO9001:2008;

- Offer detailed 2D/3D drawings;

- HS code:8207300090;

OUR ADVANTAGES:

- Rich experience from 2003;

- Reasonable die structure to save cost;

- Precision machining to guarantee the quality;

- Communication on time;

- Guarantee delivery time;

- Many years to exported dies and moulds.

Welcome you send us samples or drawings to inquiry. We will quote you the best price with high quality on time.

China microwave oven stamping die, choose Hiparter! Hiparter, Your Smart Choice!

Microwave Oven U-section Stamping Die

- Place of Origin: Qingdao, China;

- Brand Name: Hiparter;

- Shaping Mode: Punching Mold;

- Product Material: Metal;

- Die Type: Progressive Die;

- Rich experience over 12 years;

- ISO9001:2008;

- HS code:8207300090;

- Spare parts: MISUMI;

- Offer detailed 2D/3D drawings.

OUR ADVANTAGES:

- Rich experience from 2003;

- Reasonable die structure to save cost;

- Precision machining to guarantee the quality;

- Communication on time;

- Guarantee delivery time;

- Many years to exported dies and moulds.

Metal Strip for Progessive Die:

Discuss on Spot:

Welcome you send us samples or drawings to inquiry. We will quote you the best price with high quality on time.

Before delivery the stamping die, we can paint it with the color you prefer.

Paint the stamping die with green color:

The cover or outer case of the microwave oven is usually a one-piece, wrap-around metal enclosure. The oven's inside panels and doors are made of galvanized or stainless steel and are given a coating of acrylic enamel, usually light in color to offer good visibility.

China microwave oven stamping die, choose Hiparter! Hiparter, Your Smart Choice!

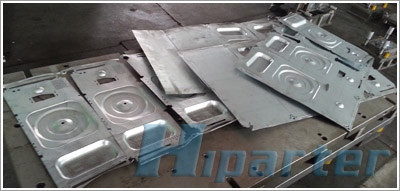

Microwave Stove Sheet Metal Parts

microwave stove sheet metal parts

1) parts material: SUS430

2) die material:SKD11, Cr12mov

3) die type:stage stamping dies

4) die life:300,000 shots

Related Stamping Die:

Microwave Stove Door Panel

1) Part material: ST14;

2) Material Thickness:0.5mm;

3) Die life:500,000 shots;

4) Punch of standard: PUNCH;

5) Die Type: Stage;

6) Stages: Drawing, drawing,trimming&piecing,flanging, flanging&forming, piercing

Our advantages:

1)Located in Qingdao,which is home appliance city with famous Haier, Hisense, Aucma;

2)Reasonable die structure to save cost, also guarantee the quality of products;

3)Tracking every steps for manufacturing the dies, to ensure the lead time;

4)Feedback in 24 hours;

5)All employees intend to make each product with zero defect;

6)Design software: AUTOCAD, UG, Pro/e, Solid works;

7)2~5 samples will be send to customers for inspection or assembly before shipping;

8)Advanced manufacturing, measuring and testing equipments

Final Part:

The oven cavity and door are made using metal-forming techniques and then painted using electro-deposition, in which electric current is used to apply the paint.

Related Microwave Stove Parts Stamping Die Pictures:

The cooking chamber is in fact a Faraday chamber, and it prevents the waves from coming out of the oven. The oven door usually has a window for easy viewing, but the window has a layer of conductive mesh some distance from the outer panel to maintain the shiel

Find What You Want

Home Appliance Parts

Progressive Dies

Deep Drawing Dies

Tags

Latest Home Appliance Dies

-

Single Door Refrigerator Beam Stamping die

Read 2449 times

1.Tool type: Stamping die; 2.Tool life:More than 500,000 shoots; 3.Machining Tolerance:0.02mm: 4.Tool Material:Mo-Cr steel, CR12MOV, CR12, 45#; 5.Standard parts: PUNCH,…

1.Tool type: Stamping die; 2.Tool life:More than 500,000 shoots; 3.Machining Tolerance:0.02mm: 4.Tool Material:Mo-Cr steel, CR12MOV, CR12, 45#; 5.Standard parts: PUNCH,… -

Microwave Oven Inner Metal Door

Read 15043 times

The microwave oven cavity/chassis and door are made by metal-forming techniques, and then painted by electro-deposition, in which electric current…

The microwave oven cavity/chassis and door are made by metal-forming techniques, and then painted by electro-deposition, in which electric current… -

Metal Moulds for Micro Wave Oven

Read 6585 times

metal moulds for micro wave oven 1) rich experience on metal stamping moulds 2) making many kinds of home appliance…

metal moulds for micro wave oven 1) rich experience on metal stamping moulds 2) making many kinds of home appliance… -

Qingdao custom Steel Metal Progressive Microwave Oven Stamping Die

Read 3253 times

•Hiparter made the microwave oven cavity, bottom plate and back panel. •The material strip shown in the left picture is…

•Hiparter made the microwave oven cavity, bottom plate and back panel. •The material strip shown in the left picture is…