Part Material: CuZn Alloy;

Made in China.

Die Specifications:

- Die type: progressive die;

- Rich experience from 2003;

- Spare parts: PUNCH, MISUMI Standard;

- Die life:1000,000 shots;

- Lead time: 50 days;

- ISO9001:2008 by SGS;

- Payment: TT;

- Delivery: By sea;

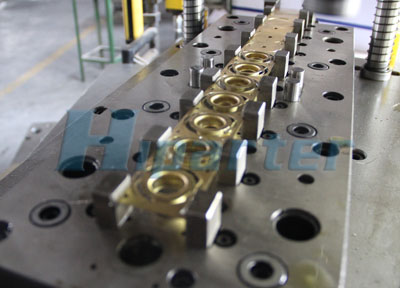

Metal Strip from Progressive Die for Brass Deep Drawing Parts:

Advantages of service:

1. Rich experience;

2. Resonable die structure to save stamping die cost;

3. Quick-change system, you can repair or maintain the dies conveniently when the dies on press machine;

4. In-house for all the machining work;

5. One-stop service.

Use Progressive Die to Make The Brass Drawing Parts:

Production in batch:

In common, before delivery the stamping die, we'll produce the parts in a little batch to guarantee the die will work with no problem in our customer's workshop.

Package and delivery:

When delivery the die, the parts will be shipped with dies to customers.

Deliveried from Qingdao Port.