High Quality Progressive Deep Drawing Die

High Precision Progressive Deep Drawing Die

Part Material:Metal Alloy;

Material Thickness:2.4mm;

Die type:Progressive;

Die Size:1576*500*493.4;

Press Machine:200T;

Year of Manufacturing: 2015;

Exported to: America;

FOB:Qingdao,China

With TD treatment to guarantee the perfect outer quality and continuous production stability.

Related Progressive Drawing Dies Pictures:

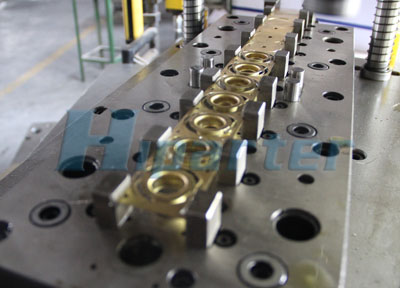

Metal Strip and The Stamping Die:

Customer at Spot for Tool Trial:

Progressive Draw Die

Part Material: CuZn Alloy;

Made in China.

Die Specifications:

- Die type: progressive die;

- Rich experience from 2003;

- Spare parts: PUNCH, MISUMI Standard;

- Die life:1000,000 shots;

- Lead time: 50 days;

- ISO9001:2008 by SGS;

- Payment: TT;

- Delivery: By sea;

Metal Strip from Progressive Die for Brass Deep Drawing Parts:

Advantages of service:

1. Rich experience;

2. Resonable die structure to save stamping die cost;

3. Quick-change system, you can repair or maintain the dies conveniently when the dies on press machine;

4. In-house for all the machining work;

5. One-stop service.

Use Progressive Die to Make The Brass Drawing Parts:

Production in batch:

In common, before delivery the stamping die, we'll produce the parts in a little batch to guarantee the die will work with no problem in our customer's workshop.

Package and delivery:

When delivery the die, the parts will be shipped with dies to customers.

Deliveried from Qingdao Port.

Curling Sheet Metal Die

Curls can be fabricated through kinds of types, including roll forming, stamping, leaf bending, and on a traditional press brake.Curling on a panel or leaf bender is often limited to off center curls because most panel benders do not have tooling profiles which can create the necessary down bend to put the curl on center.

The smaller radius is formed first to allow the material to finish inside itself. The process of step bending involves producing very small bends which are very close to each other, and while the finished bend is technically a polygon, it’s often impossible to detect the steps if they are formed correctly.

For lighter gauges parts, a hand operated panel bender can be the most affordable method for creating a curl.

Forming a Curl on Brake Press

Most curls can be formed in three stages and some setups require two tooling setups with specialized tooling for each stage. The first 2 stages form the curves which are required to form the curl, and the third stage is to close the curl. A locating notch is typical for this type of tooling is needed to ensure that the first 2 stages are bent in the correct location. Below is a typical two setup, three stage tooling.

Find What You Want

Home Appliance Parts

Progressive Dies

Deep Drawing Dies

Tags

Latest Home Appliance Dies

-

Flange of Water Heater

Read 6758 times

Water heater heater flange stamping dies manufacturer--Hiparter. With about 10 years' rich experience since 2003; Located in Qingdao, China, the…

Water heater heater flange stamping dies manufacturer--Hiparter. With about 10 years' rich experience since 2003; Located in Qingdao, China, the… -

Microwave Oven U-section Stamping Die

Read 17138 times

Place of Origin: Qingdao, China; Brand Name: Hiparter; Shaping Mode: Punching Mold; Product Material: Metal; Die Type: Progressive Die; Rich…

Place of Origin: Qingdao, China; Brand Name: Hiparter; Shaping Mode: Punching Mold; Product Material: Metal; Die Type: Progressive Die; Rich… -

Water Heater Cover

Read 8190 times

Professional with Kinds of Water Heater Covers. Our water heater covers have exported to almost 30 countries. With professional working…

Professional with Kinds of Water Heater Covers. Our water heater covers have exported to almost 30 countries. With professional working… -

China Progressive Die for Microwave Oven

Read 10349 times

Excellent China progressive dies supplier---Hiparter! 1)ISO9001:2008; 2)Rich experience: over 12 years; 3)Customers: Haier, Hisense, Sanyo, Midea, etc. 4)Dies are exported…

Excellent China progressive dies supplier---Hiparter! 1)ISO9001:2008; 2)Rich experience: over 12 years; 3)Customers: Haier, Hisense, Sanyo, Midea, etc. 4)Dies are exported…